-

E-Carbon Coating

A Solution to Wear and Corrosion. The future is today!

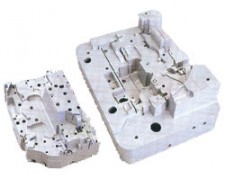

Technological advancements have now made possible the next-generation of downhole pumps for the oil industry. E-Carbon surface coating is a thin, dense composite of proprietary materials. Application of E-Carbon Coating onto standard pump components has resulted in unprecedented increases in operational life.

E-Carbon coating, with a hardness of 92+ Rc, offers today’s oil tooling design engineers and manufacturers the opportunity to achieve maximum performance levels with downhole pump equipment. E-Carbon does not fracture or separate from base metals currently being used by the petroleum industry. Bending impact and normal operational flexing will not cause the E-Carbon Coating to chip or peel. E-Carbon operates successfully at temperatures up to 1400 F (775 C) with no adverse effects on either the coating or base metal integrity.

Unlike with other metals, opposing or mating surfaces coated with E-Carbon have a greatly reduced coefficient of friction. Pump components (i.e., barrels, plungers, balls and seats) which are subject to sliding and moving contact can be coated with E-Carbon and are much easier to assemble and disassemble. Galling and fretting corrosion are essentially eliminated.

The E-Carbon coating is uniformly distributed over all surface areas. Deposit thickness tolerances are closely maintained and range between 0.001″ and 0.002″.

-

Check out our extensive product line complete with: Gaslock Products, Solid Control Systems, Corrosion Monitoring and Hard Coatings.

-

Learn more about our current systems: Five Star, Solution Valve, EVAC, High Flow, Cyclone and Optimizer.

-

We have distributors throughout the U.S., Canada, South America, Romania and the Bolivarian Republic of Venezuela.

-

Select the product literature you would like to download and review for more detailed information on any of our products.